3D printing, once considered a futuristic technology, has become a game-changer in various industries, including construction. By allowing for the creation of complex structures with precision and efficiency, 3D printing is reshaping the way buildings are designed, constructed, and maintained. This article explores how 3D printing is revolutionizing the construction industry, highlighting its benefits, applications, and the future potential of this innovative technology.

The Basics of 3D Printing in Construction

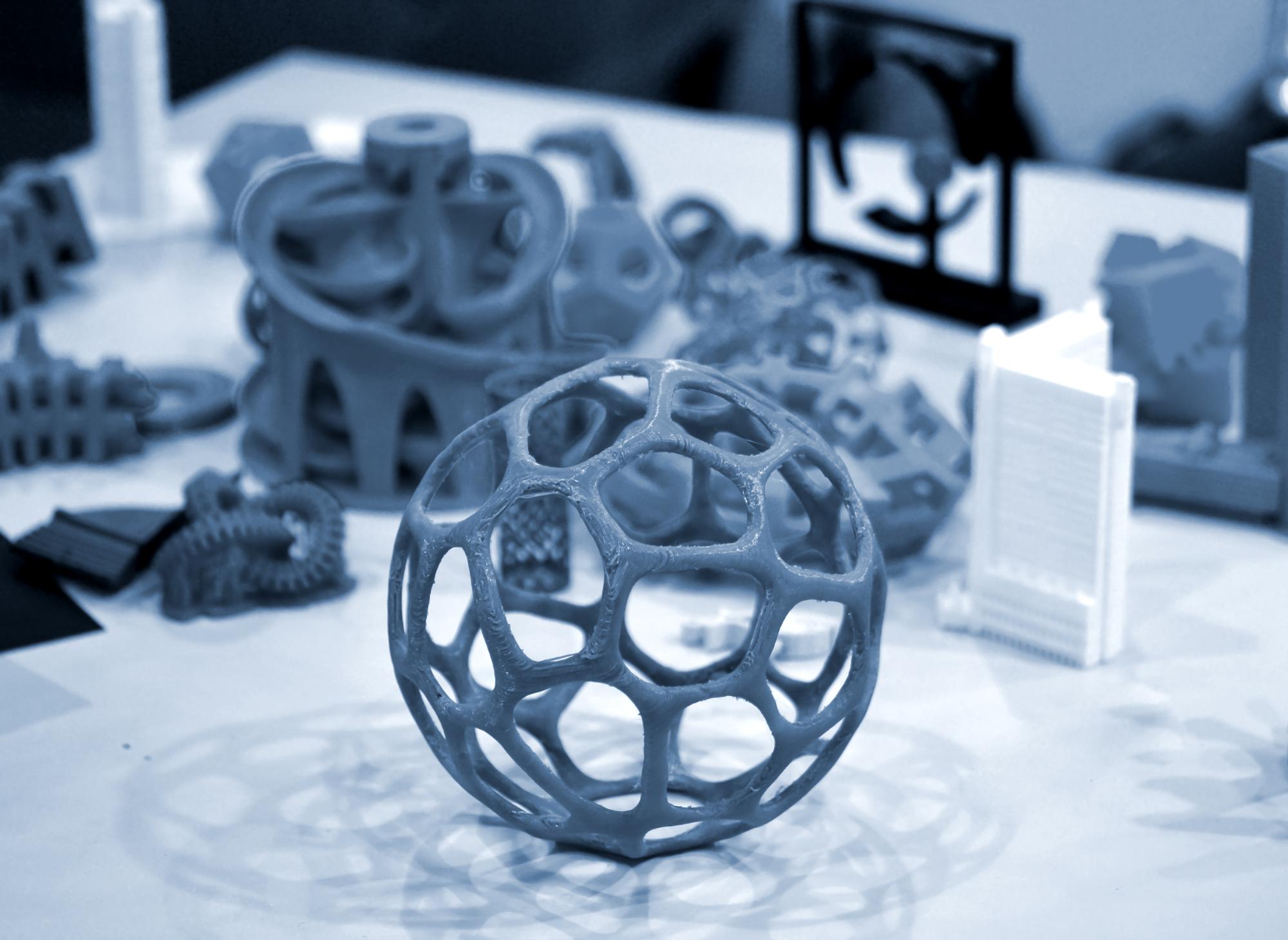

3D printing, or additive manufacturing, involves creating three-dimensional objects by layering material based on digital models. In construction, this technology uses a range of materials, including concrete, polymers, and metals, to build structures from the ground up. Here’s how 3D printing is making an impact:

Design Flexibility and Innovation

3D printing allows architects and engineers to design and construct buildings with unprecedented complexity and precision. With the ability to create intricate shapes and geometries, 3D printing opens up new possibilities for architectural design, enabling the realization of structures that were previously difficult or impossible to achieve with traditional methods.

Reduced Construction Time

One of the most significant advantages of 3D printing in construction is the reduction in build time. Traditional construction methods often involve time-consuming processes, such as formwork and manual assembly. In contrast, 3D printing can produce building components quickly and accurately, leading to faster construction timelines and reduced labor costs.

Cost Efficiency

3D printing can significantly lower construction costs by minimizing material waste and reducing the need for labor-intensive processes. The technology’s ability to use only the precise amount of material required for each component means that less waste is generated, leading to cost savings and a more sustainable approach to construction.

Applications of 3D Printing in Construction

The applications of 3D printing in construction are diverse, ranging from building entire structures to producing individual components and fixtures. Here are some notable examples:

Building Construction

Companies and researchers around the world are using 3D printing to construct entire buildings. For instance, 3D-printed houses have been developed that offer affordable, sustainable housing solutions. These homes are built using a large-scale 3D printer that extrudes concrete or other materials to form walls and structural elements, creating habitable spaces in a fraction of the time it would take using traditional methods.

Construction Components

3D printing is also being used to produce various construction components, such as bricks, tiles, and structural elements. These components can be customized to fit specific design requirements, offering greater flexibility in construction. Additionally, 3D printing can produce complex components that might be challenging to fabricate using conventional techniques.

Infrastructure Projects

Infrastructure projects, such as bridges and public amenities, are benefiting from 3D printing technology. For example, 3D-printed bridges and pedestrian walkways have been constructed to demonstrate the potential for creating durable, cost-effective infrastructure. These projects showcase how 3D printing can be applied to large-scale construction tasks, improving efficiency and innovation.

Advantages of 3D Printing in Construction

The integration of 3D printing into the construction industry brings several key advantages:

Customization and Personalization

3D printing allows for a high degree of customization in construction. Homeowners and builders can create bespoke designs tailored to individual preferences and requirements. This level of personalization is challenging to achieve with traditional construction methods and offers a unique approach to building design.

Sustainability

By reducing material waste and energy consumption, 3D printing contributes to a more sustainable construction process. Additionally, the ability to use recycled or eco-friendly materials in 3D printing aligns with the industry’s push towards greener building practices.

Enhanced Precision

The precision of 3D printing technology ensures that components are manufactured to exact specifications, reducing the likelihood of errors and the need for costly adjustments. This accuracy leads to higher quality construction and improved overall performance of building elements.

Challenges and Future Potential

While 3D printing holds great promise for the construction industry, it also faces several challenges:

Enhanced Precision

The precision of 3D printing technology ensures that components are manufactured to exact specifications, reducing the likelihood of errors and the need for costly adjustments. This accuracy leads to higher quality construction and improved overall performance of building elements.

Material Limitations

The range of materials suitable for 3D printing in construction is still limited compared to traditional building materials. Ongoing research is focused on developing new materials that offer greater strength, durability, and versatility.

Regulatory and Standards Issues

The adoption of 3D printing in construction requires updates to building codes and regulations to ensure safety and quality standards. As the technology evolves, regulatory bodies will need to establish guidelines to address these new practices.

Scalability

While 3D printing has demonstrated success in small-scale and prototype projects, scaling up to large construction projects presents logistical and technical challenges. Advances in printer size and material handling will be essential for overcoming these obstacles.

Despite these challenges, the future of 3D printing in construction is bright. As technology continues to advance, 3D printing is expected to become more widely adopted, leading to innovative and efficient building practices. The potential for 3D printing to transform the construction industry is immense, promising a new era of design, construction, and sustainability.

In conclusion, 3D printing is revolutionizing the construction industry by offering new possibilities for design, reducing construction time and costs, and promoting sustainability. As the technology progresses, its impact on the way we build and live will only continue to grow, reshaping the construction landscape for years to come.